Discover the cutting-edge world of topology optimization through Rhino Grasshopper in our latest blog post, where innovation meets efficiency in design. Learn how genetic algorithms unlock unparalleled possibilities, from lightweight aerospace components to custom medical implants and efficient heat exchangers.

Dive into a journey that transforms complex mathematical concepts into practical, groundbreaking solutions across industries, showcasing the power of integrating computational design strategies with real-world applications.

Table of Contents

What is Topology?

Topology is a branch of mathematics concerned with the properties of space that are preserved under continuous transformations, such as stretching, crumpling, and bending, but not tearing or gluing. It’s like looking at the geometric essence of objects, focusing on their structure and spatial relationships rather than their detailed geometry. Here are some key points about topology:

- Continuity and Space: At its heart, topology studies spaces and the continuous maps between them. A space in topology can be anything from a simple line or circle to complex n-dimensional manifolds.

- Topological Properties: Properties that are of interest in topology include connectivity (how a space is connected), compactness (a notion that generalizes closed and bounded sets), and continuity (a concept that is refined in topology to deal with more abstract spaces).

- Homeomorphisms: A fundamental concept in topology is the idea of homeomorphism, which is a continuous deformation from one shape into another. Two spaces are considered the same in topology if they can be transformed into each other through stretching or bending but not tearing or gluing. For example, a coffee cup and a doughnut (torus) are considered the same in topology because each can be deformed into the other without cutting or attaching.

- Branches of Topology: Topology has several subfields, such as:

- General Topology (Point-Set Topology): Focuses on the more general aspects of space, including open and closed sets, continuity, and convergence.

- Algebraic Topology: Uses tools from abstract algebra to study topological spaces, focusing on properties that are invariant under homeomorphism. Concepts such as homotopy, homology, and fundamental groups fall under this category.

- Differential Topology: Studies differentiable functions on differentiable manifolds and is closely related to differential geometry.

- Geometric Topology: Deals with low-dimensional manifolds, such as curves, surfaces, and 3-manifolds, and often involves studying their embeddings and immersions in higher-dimensional spaces.

- Applications: Beyond pure mathematics, topology has applications in many fields, including physics, computer science, and biology. In physics, for example, topology is used to study the properties of space and matter on a very fundamental level. In computer science, it provides insights into data analysis and visualization through topological data analysis (TDA).

In summary, topology offers a deep and nuanced understanding of the spatial relationships and properties that remain invariant under continuous transformations. It’s a field that bridges many areas of mathematics and finds applications in numerous other disciplines.

Topology Optimization with Grasshopper

Topology optimization is a mathematical method used in various engineering fields to optimize material layout within a given design space, for a given set of loads, boundary conditions, and constraints with the goal of maximizing the performance of the system. Grasshopper, a visual programming tool integrated with Rhinoceros 3D (Rhino), provides a platform for topology optimization in architectural and mechanical design processes. Here’s how topology optimization typically works with Grasshopper:

- Design Space Definition: The first step involves defining the design space, which is the volume or area within which the topology optimization will be performed. This space is subject to various forces and constraints.

- Objective Function and Constraints: The user must define the objective function, which could be minimizing the material volume, maximizing stiffness, or optimizing for another performance metric. Constraints such as maximum displacement, stress limits, or a specified amount of material can also be set.

- Simulation and Analysis Tools: Grasshopper, through its plugins, allows for the integration of simulation and analysis tools. These tools can perform finite element analysis (FEA) to predict how the proposed designs will perform under the specified loads and constraints.

- Optimization Algorithms: Grasshopper plugins like Galapagos, Octopus, or external tools linked through the Grasshopper environment (e.g., ANSYS, or Millipede) provide various optimization algorithms. These algorithms iteratively adjust the distribution of material within the design space to find the optimal configuration that meets the defined objectives and constraints.

- Result Interpretation and Refinement: The output from the optimization process is a material distribution that optimally meets the specified criteria. This result often needs to be interpreted and refined into a more conventional design for manufacturing or construction.

- Iterative Process: Topology optimization is typically an iterative process. Designers may adjust the design space, loads, constraints, or objective functions based on the results of previous optimizations to explore different design possibilities or to improve the design further.

- Integration with the Design Workflow: The optimized design can be further processed within Rhino Grasshopper for detailing, fabrication planning, or aesthetic adjustments. This seamless integration allows for a fluid design workflow from conceptual optimization to final design detailing.

Plugins and Tools for Topology Optimization in Grasshopper:

- Millipede: A plugin that provides structural analysis and optimization capabilities.

- Karamba3D: Mainly focused on structural analysis and optimization, it’s useful for quick feedback on the performance of designs.

- Galapagos: Grasshopper’s evolutionary solver that can be used for optimization problems, though not specifically designed for topology optimization, it can be used as part of the workflow.

- TopOpt: A dedicated topology optimization tool within Grasshopper, if available, specifically designed for this purpose.

Topology optimization in Grasshopper allows designers and engineers to explore material-efficient designs and to innovate in the creation of structures and products. The visual programming environment of Grasshopper, combined with Rhino’s modeling capabilities, makes it an accessible yet powerful tool for topology optimization in various design and engineering disciplines.

3 Ideas for Topology Optimization

Topology optimization can significantly enhance the performance and efficiency of designs across various industries by optimizing material distribution within a given design space. Here are three innovative ideas for applying topology optimization in different contexts:

1. Lightweight Structural Components in Aerospace and Automotive Industries

Objective: To reduce the weight of structural components without compromising their strength or integrity, leading to more fuel-efficient vehicles and aircraft.

Implementation:

- Utilize topology optimization to design components such as chassis parts, engine components, or wing structures. The goal is to minimize material usage while maintaining or improving structural performance under operational loads.

- Employ advanced materials like titanium alloys or carbon-fiber-reinforced polymers, which are compatible with the complex shapes resulting from topology optimization.

- Integrate these optimized components into the manufacturing process, using techniques suited to their complex geometries, such as 3D printing or composite layup.

Impact:

- Significant weight reduction leads to improved fuel efficiency and lower emissions in automotive and aerospace applications.

- Enhanced performance through designs that are structurally efficient and tailored to withstand specific load conditions.

2. Customized Medical Implants

Objective: To design medical implants (e.g., hip replacements, dental implants) that better mimic the mechanical properties of natural bone, leading to improved integration with the human body and longer-lasting implants.

Implementation:

- Apply topology optimization to design implants with varying density and structure, matching the mechanical properties of bone more closely than traditional implants.

- Focus on creating porous structures that encourage bone ingrowth and proper integration of the implant with the surrounding bone tissue.

- Use biocompatible materials that are suitable for 3D printing, allowing for the production of complex, patient-specific shapes derived from medical imaging data.

Impact:

- Improved patient outcomes through implants that are more compatible with the human body, reducing the risk of rejection or failure.

- Enhanced durability and longevity of implants, potentially reducing the need for revision surgeries.

3. Efficient Heat Exchangers

Objective: To increase the efficiency of heat exchangers used in various applications, from HVAC systems to automotive radiators, by optimizing the geometry for maximum heat transfer with minimal material use and fluid resistance.

Implementation:

- Use topology optimization to explore novel heat exchanger designs that optimize the surface area for heat transfer while minimizing the volume of material and fluid flow resistance.

- Consider factors such as the type of fluid, flow rates, and thermal properties in the optimization process to tailor designs to specific applications.

- Implement the optimized designs using manufacturing techniques capable of producing complex geometries, such as metal 3D printing.

Impact:

- Higher efficiency heat exchangers can lead to significant energy savings in cooling and heating systems, industrial processes, and automotive applications.

- Reduced material use and improved performance contribute to more sustainable and cost-effective operations.

Each of these ideas showcases the potential of topology optimization to revolutionize design and manufacturing across different sectors by enabling the creation of innovative, efficient, and tailored solutions that meet specific performance criteria.

Genetic Algorithms for Topology Optimization

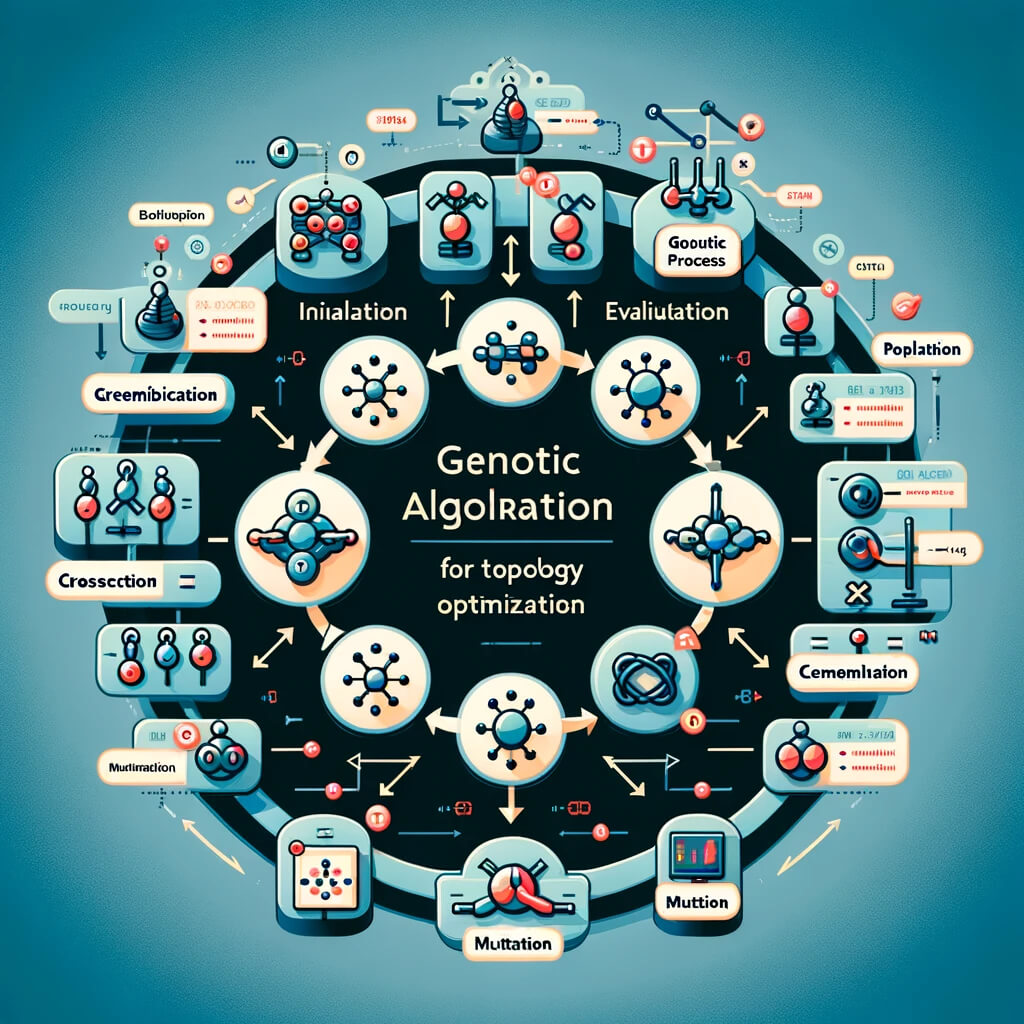

Genetic algorithms (GAs) are a type of evolutionary algorithm inspired by the process of natural selection. They are particularly effective for solving optimization and search problems where the search space is large, complex, or poorly understood. When applied to topology optimization, genetic algorithms can efficiently explore a wide range of design alternatives to find optimal or near-optimal solutions that satisfy specific performance criteria. Here’s how genetic algorithms can be applied to topology optimization:

1. Initialization

- Design Space: Define the problem’s design space, including the boundaries and constraints of the physical system (e.g., available volume for material distribution).

- Population: Generate an initial population of design solutions, often represented as binary strings, arrays, or more complex data structures that indicate the presence or absence of material at discrete points within the design space.

2. Evaluation

- Objective Function: Define one or more objective functions to evaluate the performance of each design solution. In topology optimization, this could be minimizing material usage while maximizing structural strength or thermal performance.

- Fitness Calculation: Calculate the fitness of each design solution based on the objective function(s). Higher fitness scores are assigned to solutions that better meet the optimization criteria.

3. Selection

- Select design solutions for reproduction based on their fitness, using methods like roulette wheel selection, tournament selection, or rank-based selection. This step mimics natural selection where fitter individuals are more likely to reproduce.

4. Crossover (Recombination)

- Combine pairs of selected design solutions to create offspring, sharing features of both parents. This can involve swapping sections of their representations (e.g., binary strings) to mix their material distributions.

5. Mutation

- Introduce random changes to the offspring designs to explore new parts of the design space. This could involve flipping bits in a binary representation or making small alterations to the material layout.

6. Replacement

- Replace some or all of the older generation with the new offspring, often keeping the best-performing solutions (elitism) to ensure quality does not decrease over generations.

7. Iteration

- Repeat the evaluation, selection, crossover, mutation, and replacement steps for many generations until a termination condition is met, such as reaching a maximum number of generations or achieving a satisfactory level of fitness.

Advantages of Using GAs for Topology Optimization:

- Exploration of Complex Spaces: GAs are highly effective in navigating complex, multimodal design spaces where traditional gradient-based optimization methods might struggle or get trapped in local minima.

- Parallelizability: The population-based approach of GAs lends itself well to parallel computation, allowing for the evaluation of many design solutions simultaneously.

- Flexibility: GAs can handle multiple objectives and constraints, making them suitable for complex engineering problems where trade-offs between different performance metrics must be considered.

Challenges:

- Computation Time: The stochastic nature of GAs and the need for numerous evaluations can lead to high computational costs, especially for complex problems.

- Solution Precision: GAs may find approximate solutions that are near-optimal, but fine-tuning might be necessary to reach the precise optimal solution.

Applications:

Genetic algorithms have been successfully applied to topology optimization in various fields, including structural engineering for optimizing beam layouts and materials, aerospace for designing lightweight structures, automotive for crashworthiness design, and even microscale applications like the layout of heat sinks or photonic waveguides.

Conclusion

This comprehensive blog post delves into the fascinating world of topology optimization using Rhino Grasshopper, showcasing its potential to revolutionize design across various sectors through material efficiency and innovative solutions.

By integrating genetic algorithms, the post highlights a methodical approach to navigating complex design spaces, optimizing for structural integrity, medical applicability, and thermal efficiency.

It emphasizes the synergy between advanced computational techniques and practical engineering applications, underscoring the transformative impact of topology optimization on future design and manufacturing processes.